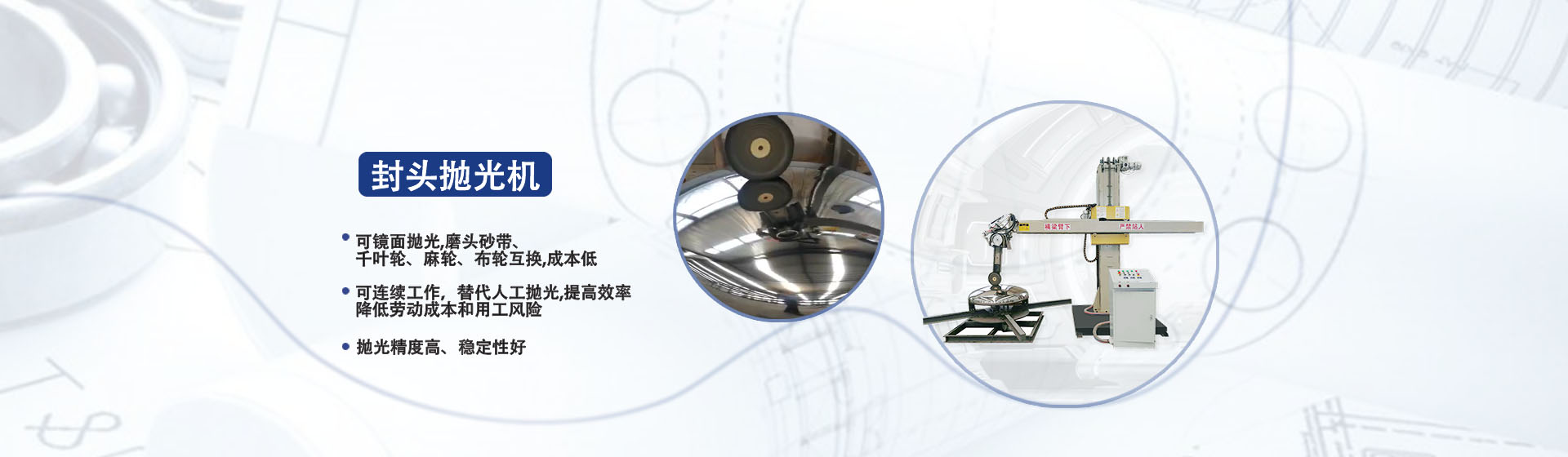

Transportation manufacturers necessitate the highest levels of precision in components. A critical aspect is achieving a pristine surface on hollow finishes, which can be tough with traditional systems. Our cutting-edge Precision Dished EndAC Polishing Machine meets this necessity by granting an automatic and meticulous strategy. This contraption employs custom tooling and a monitored polishing method to produce a polished finish on hollow finishes, maintaining optimal operation and endurance of automotive units.

- The machine’s programmable interfaces grant for precise fine-tuning to the polishing settings, validating regularity and reproducibility.

- Its space-saving structure boosts workspace performance while curtailing operator exhaustion.

- Merging with existing manufacturing systems is uncomplicated, accelerating production chains.

Robust Tank Polishing Machines for Stainless Steel Fabrication

In the sector of stainless steel production, reaching a flawless and polished sheen is key. To complete this undertaking, high-efficiency tank polishing machines have arisen as key equipment. These cutting-edge machines apply cutting-edge technology to rapidly clear surface roughness and enhance a gleaming sheen on stainless steel tanks.

- Besides, high-efficiency tank polishing machines are crafted for optimal operation, boasting durable construction, solid motors, and innovative polishing heads that diminish surface damage.

- Therefore, fabricators can maximize exceptional results with minimal effort, refining their production workflows and yielding high-quality tanks that fulfill the stringent expectations of various branches.

Cutting-Edge Cylindrical Polishing System for Precision Engineering

The call for exceptional surface accuracy in precision engineering is constantly rising. To cope with these rigorous prerequisites, a original cylindrical polishing system has been developed. This advanced technology makes use of cutting-edge mechanisms to attain unparalleled surface precision. It successfully removes imperfections and improves the overall performance of cylindrical segments across a wide range of areas.

- Gains include increased throughput, reduced manufacturing budgets, and improved product reliability.

- The system is configured to handle a diverse range of substances, including metals, ceramics, and plastics.

- Technicians can easily adjust the polishing specifications to deliver the desired look.

This advanced cylindrical polishing system represents a significant leap forward in precision engineering, permitting manufacturers to produce modules of exceptional merit and efficiency.

Automated CNC Polishing Solutions for Complex Shapes

Gaining a spotless finish on intricate designs can be a demanding task. Traditional polishing methods often struggle to generate consistent results on complex structures, leading to time-consuming repetitions. However, the advent of intelligent CNC polishing solutions has upgraded the industry, permitting manufacturers to achieve unprecedented degrees of accuracy and efficiency.

These high-tech systems make use of programmed machining technology to finely hone surfaces with minimal operator intervention. Equipped with automated spindles and a variety of polishing tools, CNC machines can easily handle even the most demanding designs.

Additionally, these solutions offer refined control over parameters such as pressure, speed, and tool path, ensuring consistent results across different materials and complexities.

- Advantages of automated CNC polishing include:

- Elevated precision and surface grade

- Cut cycle times and production costs

- Bettered product consistency and repeatability

- Broader design flexibility for complex shapes

Sturdy Tank Polishing Machine for Industrial Applications

For demanding industrial situations where capability is indispensable, a robust tank polishing machine is an necessary tool. These machines are specifically constructed to handle the demands of regular operation in hostile environments. Equipped with durable construction and high-torque motors, they can effectively extract rust, paint, and additional contaminants from tank surfaces, providing a smooth and sanitary finish. A variety of brushes are available to accommodate different tank sizes and patterns, making them versatile for a wide range of applications.

Adaptive Control-Equipped Dished End Polisher

Our cutting-edge Dished End Polisher integrates intelligent Adaptive Control Technology to deliver unparalleled output. This process continuously regulates the polishing process in real time, guaranteeing optimal surface sheen for a wide range of substances. The Adaptive Control Technology facilitates the adjustment of key factors, such as pressure, speed, and oscillation, to achieve precise results every time.

- Advantages include:

- Strengthened surface finish quality

- Decreased polishing time

- Greater control over the polishing process

- Multifunctionality for a range of materials and applications

Computerized Polishing Unit for Superior Surface Treatment

A CNC polishing device is a effective tool utilized in various markets for delivering superior surface finishes. These machines use computer numerical control (CNC) technology to rigorously polish surfaces, eradicating imperfections and creating a smooth, refined appearance. The advanced design of CNC polishing machines enables for individualized processing.

- Manufacturing processes

- Ceramics

- Refining details

The digital nature of CNC polishing machines secures repeatable results, lessening human error and enhancing efficiency. By leveraging a variety of finishing tools, these machines can process a broad spectrum of surface varieties and components.

Machining Equipment for Large Cylinders

Manufacturing and polishing large diameter cylindrical modules often involves specialized equipment. These machines are manufactured to meet precise dimensional tolerances on objects with significant girth, making use of a variety of surface enhancers.

The choice of cylindrical polishing equipment is strongly influenced by the specific material and desired outcome. Some common types include spin polishing systems, each offering distinct advantages for removing burrs.

- Retention units are essential to securely hold large diameter pieces throughout the treatment process.

- Controlling spindle velocity and feed are critical for securing consistent results.

High-Speed Dished End Polishing Machine for Mass Production

In contemporary rapidly advancing manufacturing industry, the requirement for cost-effective high-volume production programs is indispensable. To fulfill this task, manufacturers are implementing cutting-edge technologies like high-speed dished end polishing machines. These high-tech systems deliver exceptional exactness in a time-sensitive manner, securing consistent quality and exemplary surface finishes for a broad range of components.

Configured to handle large production runs with exceptional speed, these machines apply advanced polishing techniques to generate spotless finish required for demanding applications. Key features include high-speed spindles, intelligent control systems, and innovative grinding pads that work in synergy to maximize effectiveness.

As well, these machines often incorporate automation mechanisms for increased results and reduced labor costs. This combination of speed, accuracy, and robotics makes high-speed dished end polishing machines a vital asset for manufacturers working to maximize their production processes and handle the growing requirements of the market.

Meticulous CNC Polishing for Aerospace and Diagnostic Devices

In the critical fields of aerospace and medical device engineering, surface texture is fundamental. CNC polishing grants a highly refined and secured method to produce the exacting coatings required for these critical applications. By employing advanced CNC machining technology, manufacturers can create surfaces with exceptional polish, precision, and longevity. This process makes possible the production of components that observe stringent expectations for efficiency, reliability, and protection.

- preferences expectations expectations requirements expectations

- Besides, CNC polishing improves the decay resistance and biocompatibility of elements used in aerospace and medical devices.

- Subsequently, it plays a vital role in extending the lifespan and enhancing the efficiency of these products.

Configurable Cylindrical Polishing System for Customization

Unveiling a revolutionary system to cylindrical polishing: the Modular Cylindrical Polishing System. This cutting-edge system empowers unparalleled customization, catering to your specific specifications. With its adaptable design, you can easily adjust the polishing heads, units, and parameters to deliver the optimal finish for your cylindrical objects.

- demands expectations tank polishing machine preferences

- Asset1

- Advantage2

- Strength3