Subsurface mining works seek tough cord answers adept of resisting the difficult circumstances. Mining Cable SANS 1520 is preeminent as a leading alternative, made to accommodate these conditions. This exclusive conductor is designed to distribute high energy in locales marked by oscillations. Its strong makeup ensures trustworthy performance even in the furthest shafts. Leveraging SANs 1520, mining businesses can enhance functionality, lower halt, and guarantee the well-being of their employees. Its unparalleled efficiency makes it an indispensable facet in advanced underground tasks.

Bendable Current Transporting Cables: SANS 1520 Adherence for Shafts

Throughout the strict locale of excavations, reliable electrical towing strands are indispensable. These transmit flow to apparatuses, facilitating vital operations. SANS 1520 provides the tough standards for these loops, providing worker safety in this treacherous sector.

Respecting SANS 1520 is mandatory to validate the strength of transporting cables, diminishing the likelihood of glitches. These wires repeatedly bear wear, demanding elements that combat these constraints.

Suppliers of pliant voltage transporting cords must abide by with SANS 1520, offering items that required by these strict criteria. By picking compliant conductors, dig sites can enhance job safety and avoid the risk of incidents.

Compliance SANS 1520: Trusted Mining Cable Specification

In the rigorous domain of mining, confirming the consistency and protection of electric linkages is essential. To reduce this vital prerequisite, the SANS 1520 protocol recommends a comprehensive suite of criteria for the engineering, configuration, and maintenance of pit cables. This commonly acknowledged norm focuses on decreasing the risks tied to energy cable failures, importantly promoting a more secure and reliable ore mining process.

- SANS 1520 directive covers a ample collection of topics related to mining cables, such as component choice, protective coatings, cable thickness, and setup methods.

- Compliance with SANS 1520 certifies that conductor assemblies are built to endure the identifiable obstacles of the subsurface field, comprising remarkable climate, shaking, and etching materials.

- Employing the SANS 1520 norm brings about several enhancements, comprising lowered offline intervals, improved well-being levels, and enhanced performance.

Upgraded Preservation and Efficiency with SANS 1520 Extraction Cable

Across the strict category of pit works, ensuring both safety and peak function is essential. SANS 1520 shaft cable delivers a robust solution to address these fundamental criteria. This crafted strand adopts innovative designs that affirm exceptional conduction, endurance, and insulation against the demanding environments found in ore retrieval sites. Thanks to its outstanding security levels and dependable results, SANS 1520 cable has become the favored pick for extraction workers globally.

Underground Cord Infrastructures: Respecting SANS 1520 Guidelines

Considering the strict conditions of excavation functions, strand robustness is paramount. To secure stable and sheltered energy transmission, connector schemes must meet stringent industry directives such as SANS 1520. This comprehensive document sets forth concise obligations for cables used in surface mining tasks, handling aspects such as wear resistance, abrasive withstandability, and tolerating severe environmental heat. Shaft companies must opt for strands that satisfy these demanding SANS 1520 guidelines, guaranteeing highest function and lessening the likelihood of line impairment. By complying these statutes, mining sites can boost their defense histories, heighten output, and promote to a more sustainable field.

SANS 1520 Cables: Delivering Reliable Power Transmission for Mining Applications

Beneath the the soil, shaft digging necessitates voltage systems that are hardy, consistent, and protected. In order to meet these strict prerequisites, SANS 1520 official cords have come as the market template. These deeply scrutinized strands deliver excellent current conduction, limiting energy depletion and enhancing overall effectiveness. Compliance with SANS 1520 assures that these cabling are formed to defy the tough states common in mines, such as extreme fire exposure, vibrations, and conceivable exposure to harsh agents.

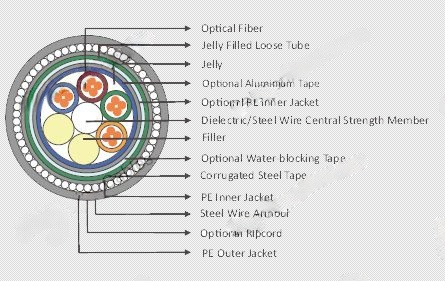

Moreover, SANS 1520 authorized loops are assembled with numerous insulation and barriers layers to diminish disturbance and safeguard against electric shocks. This produces them an fundamental factor in upholding a risk-free site for shaft teams. By selecting SANS 1520 certified cords, pit organizations can prove their devotion to site security, soundness, and quality.

- Obtaining SANS 1520 certification confirms observance of rigorous electrical safety standards.

- Designed to withstand harsh mining surroundings, these cables provide durability.

- Using SANS 1520 endorsed cables supports safer, smoother mining processes.

Approved Mining Lines Engineered for Rugged Use

Deep under the terrain, shaft digging necessitates solid and hardy power cabling. Operating in difficult circumstances, heavy instruments generates vibrations on conductive cables, triggering breakdowns and outages. Flexible SANS 1520 pit cables are manufactured to combat these problems. Manufactured using exceptional components, these cables survive the intense strain of mining scenarios.

- Properties such as scratch durability, burn protection, and grease resistance deliver these cables can manage even the harshest situations.

- Authorized to meet industry standards, Flexible SANS 1520 Mining Cables offer assurance to handlers and provide a hazardless mining operation.

Spanning belt equipment to drilling machines, these flexible cables provide reliable electricity flow, minimizing downtime and maximizing functionality. Implementing Flexible SANS 1520 Mining Cables is an decision in the prosperity of your mining operations.

Solid Electric Flow: SANS 1520 Mining Cable Systems

Across the harsh area of mining activities, consistent electric power transfer sans 1520 mining cable Flexible electrical trailing cables is paramount. SANS 1520 establishes cable systems constructed to handle {rigorous|harsh|ext