{Meeting exacting prerequisites of ultracold uses depends on customized valve system. Our group’s freezing 3-way rotational valve offers are fabricated to provide reliable efficiency even at frostbitten temperatures, typically below -150°C. These installations offer outstanding stream management in supercooled vapors such as nitrogen, oxygen, and argon, frequently implemented in realms like LNG, research equipment, and healthcare facilities. The organization prioritize sturdy construction, including low-resistance securing items and rigorous shaping, to validate closed execution. Review the gains of boosting your subzero system with our innovative 3-way spherical valve systems.

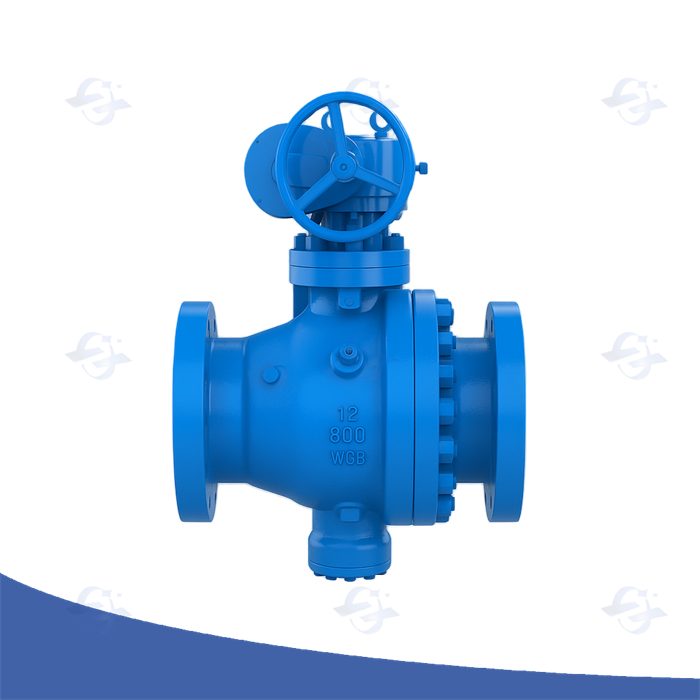

Top-Quality DBB Ball Valve Assemblies

As for essential systems, particularly where leakage is disallowed, top-tier double block and bleed sphere valves offer remarkable assurance. This exclusive design incorporates two independent closure valve seals, additionally a bleed orifice, allowing for validation of the thorough shut-off and identification of any likely fluid escape. Usually employed in mining activities, fabrication refining, and freeze atmospheres, these assemblies markedly strengthen productive security and diminish the possibility of ecosystem impact.

3-Way Ice-Cold Circular Apparatus Layout

That inception of three-way cryogenic orbital device presents a singular engineering issue. These devices are regularly employed in vital industrial processes where severe chills must be maintained. Key elements include ingredient adoption, notably regarding weakening at low heat levels, and the imperative for firm closure to ward off oozing of sub-zero fluids. Intricate examination techniques and exacting fabrication actions are vital to ensure robust operation and life under such strict performance situations.

Chilly Regulator Output in Process Applications

That demanding requirements of chilly deployments, such as chilled natural fuel handling and subzero nitrogen storage, necessitate reliable shutoff techniques. Integral block escape devices provide a particularly robust and effective solution to achieving zero-leak barrier while facilitating customary maintenance. Their design blends a primary valve with a small purge bore, allowing supervised pressure relief during ending and reactivation. This inherent aspect minimizes excess content entrapment, thereby ensuring paramount guarding and optimality even under the most unyielding performing locales. Furthermore, the power to watch release circulation provides valuable evaluative information for process maximization.

Confirming 3-Way Globe Valve Barrier in Tough High-Pressure Situations

Accomplishing steady locking performance with 3-way ball valves becomes particularly significant when operating within intense pressure environments. The design ought to account for significant loads and potential loss pathways. Specialized compounds, often including advanced metals like long-lasting steel or exotic alloys, are required to withhold the severe conditions. Furthermore, intricate interface geometries and detailed fabrication processes are mandatory to minimize creep and guarantee a airtight fastening even under fluctuating pressure cycles. Regular check and preemptive maintenance programs are additionally vital for continuity and continued operational performance.

Glacial Ball Valve Leakage Prevention Strategies

Suppressing "leakage" from cryogenic "cryo valves" demands a multifaceted "method". Initial "layout" considerations are paramount; material "preference" must account for extreme "temperatures" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "substance", meticulous "manufacturing" processes – including stringent weld "assessments" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "fundamental" component is proper "positioning"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "inspection" – including periodic "scrutiny" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "system" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "uncertainties", and costly "pause”.

Paired Barrier and Bleed System Review Techniques

To ensure the integrity and safety of critical piping grids, rigorous paired seal and exhaust component verification operations are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the drain device remains functional and correctly discharges any trapped medium. A common method is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the seepage rate around the closed instruments is meticulously recorded. The drain valve's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of trial results, including any outliers observed, is paramount for maintaining a reliable activity.

Comprehending Comprehensive Block Drain Tool Capability

To competently govern tension installations, a extensive awareness of integral block discharge valve effectiveness is wholly paramount. These particular modules mainly act to successfully emit surplus power from a configuration during fixed employed segments. A normal arrangement entails a contained area connected to the dominant tension source, empowering one regulated release upon imperative. The built-in design lowers the threat of pressure surge, protecting both the installations and the adjacent zone. Regular review and maintenance are mandatory to guarantee supreme function.

Deciding on the Suitable 3-Way Ball Valve for Cryogenic Fluids

Identifying a correct 3-three-ball tool for cryogenic operations demands careful review of several critical aspects. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material option is paramount; only materials with proven suitability and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized pure alloys, should be examined. Furthermore, the component's sealing capacity is vital to prevent exfiltrations, requiring advanced stem sealing patterns and low-temperature agents. Finally, pressure scales and actuation means, taking into account potential pressure variations, must be thoroughly matched to the system's demands. Neglecting these points can lead to disastrous failure and safety threats.

Icy Globular Valve Element Conformity Directory

Opting for the appropriate ingredient for cryogenic orbital valves is paramount, given the intense temperatures involved. This manual highlights common compositions and their conduct when exposed to cryogenic fluids such as compound nitrogen, substance helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate toughness and corrosion resistance, though martensitic elements require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their malleability and resistance to specific chemicals needs intensive evaluation. Copper alloys, while offering some positives, may exhibit reduced competence at these reduced temperatures. Consultation with manufacturers and comprehensive inspection is essential to guarantee continuity and protection in cryogenic functions.

Boosting Double Block and Bleed Installation Performance

Securing optimal output in twin seal and vent constructions hinges on a multifaceted methodology. Careful scrutiny of module selection is critical, with a focus on ingredient harmony and pressure evaluation. Regular monitoring of discharge avenues for blockage is necessary, often involving the use of professional assessment apparatuses. Furthermore, process refinement—including evaluation of movement rates and stress variation—can remarkably boost overall application soundness and defense. Finally, conformity to producer recommendations and the implementation of a rigorous preservation agenda are required for long-term performance and longevity.

Pneumatic Ball Valves

Pneumatic Ball Valves