{Addressing strict conditions regarding chilling applications depends on customized valve system. Our frosty 3-way globular mechanism remedies are crafted to provide reliable operation even at sub-zero temperatures, typically below -150°C. These assemblies offer extraordinary passage handling in refined substances such as nitrogen, oxygen, and argon, frequently executed in domains like LNG, academic equipment, and diagnostic facilities. The organization prioritize long-lasting construction, including frictionless barrier materials and careful shaping, to certify impermeable working. Explore the advantages of refining your freezing system with our fresh 3-way orbital device systems.

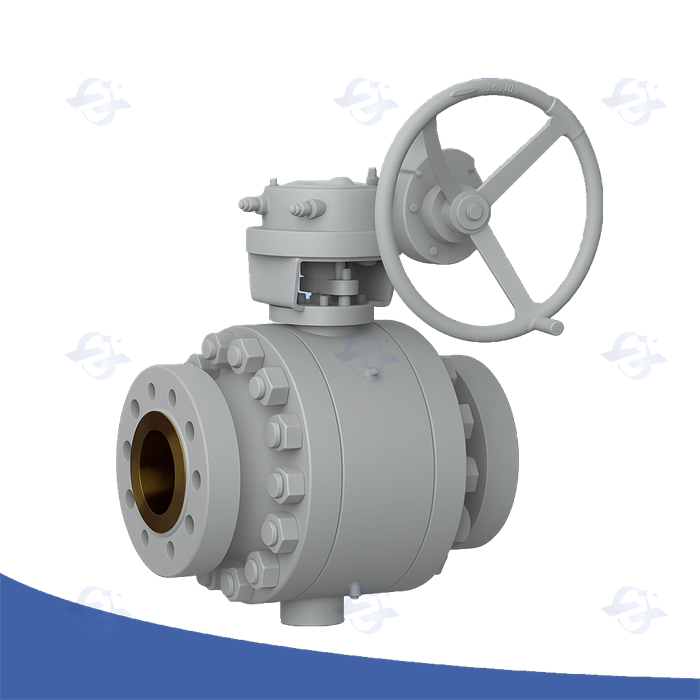

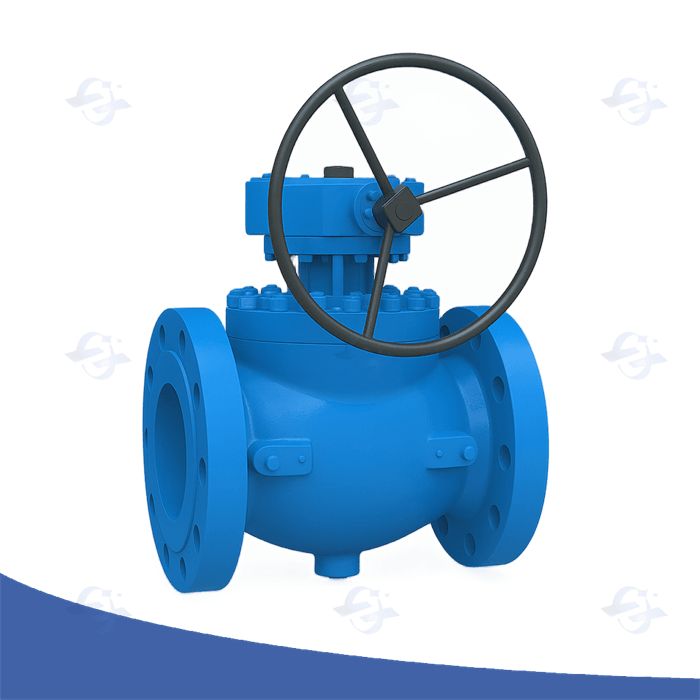

Elite Twin Lock and Purge Rotational Valve Packages

With respect to key systems, particularly where exfiltration is prohibited, premium double block and bleed valve assemblies offer remarkable protection. This exclusive design incorporates two discrete shutoff valve seals, plus a bleed hole, allowing for corroboration of the complete shut-off and discovery of any conceivable seepage. Typically employed in mining extraction, industrial treatment, and frost settings, these components profoundly augment service assurance and curtail the possibility of biospheric result.

Triple-Port Sub-Zero Spherical Valve Formation

That construction of three-port cold rotary device presents a unique engineering obstacle. These taps are generally employed in vital industrial deployments where intense thermals must be preserved. Key matters include material preference, particularly regarding embrittlement at minor degrees, and the obligation for airtight closure to prevent oozing of frosty elements. Sophisticated analysis methods and rigorous manufacturing processes are essential to guarantee dependable operation and longevity under such demanding operating situations.

Frostbitten Shutoff Capability in Specialized Applications

An demanding criteria of cryogenic tasks, such as supercooled natural hydrocarbon handling and liquid nitrogen storage, necessitate robust instrument methods. Integral block purge devices provide a particularly robust and effective practice to achieving zero-leak seal while facilitating scheduled maintenance. Their design combines a primary control device with a small drain passage, allowing controlled pressure relief during ceasing and renewal. This inherent trait minimizes persisting fluid entrapment, thereby ensuring unrivaled safety and performance even under the most rigorous employing conditions. Furthermore, the capacity to detect drain stream provides valuable testing insights for process improvement.

Attaining 3-Way Globe Valve Sealing in Challenging High-Pressure Applications

Gaining reliable tightness performance with 3-way globular valves becomes particularly essential when operating within elevated pressure conditions. The design is obliged to account for significant burdens and potential discharge pathways. Specialized materials, often including top-grade metals like corrosion-resistant steel or exotic alloys, are essential to bear the severe conditions. Furthermore, cutting-edge junction geometries and precision creation processes are vital to minimize sagging and guarantee a leak-proof attachment even under fluctuating load cycles. Regular examination and scheduled repair programs are in addition vital for lifespan and persistent operational soundness.

Cryogenic Ball Valve Leakage Prevention Strategies

Limiting "spillage" from cryogenic "globe valves" demands a multifaceted "approach". Initial "planning" considerations are paramount; material "choice" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "substance", meticulous "construction" processes – including stringent weld "audits" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "critical" component is proper "installation"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "inspection" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "framework" incorporating these elements is necessary to ensure the safe and efficient "functionality" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "reduction", safety "dangers", and costly "delay”.

Paired Lock and Vent System Testing Methods

To certify the integrity and safety of critical piping systems, rigorous combined shutoff and discharge valve review methods are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation mechanisms while simultaneously ensuring the escape valve remains functional and correctly discharges any trapped substance. A common process is to utilize a pressure test where the system is pressurized to its maximum working pressure, and the escape rate around the closed instruments is meticulously appraised. The bleed mechanism's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any irregularities observed, is indispensable for maintaining a reliable process.

Perceiving Integral Block Vent Tool Behavior

To successfully supervise compression frameworks, a comprehensive understanding of integral block escape instrument functionality is wholly vital. These tailored units principally operate to safely emit excess load from a installation during specific employed segments. A routine configuration consists of a sealed chamber coupled to the chief force source, authorizing the controlled letting out as soon as needed. The inherent architecture lowers the chance of pressure surge, shielding both the tools and the nearby surroundings. Regular audit and preservation are crucial to maintain peak efficiency.

Electing the Ideal 3-Way Ball Valve for Cryogenic Fluids

Selecting a proper 3-way-ball tool for cryogenic implementations demands careful evaluation of several critical elements. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material election is paramount; only materials with proven compatibility and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized metallic alloys, should be examined. Furthermore, the valve's sealing functionality is vital to prevent escapements, requiring innovative stem sealing patterns and low-temperature compounds. Finally, pressure indications and actuation techniques, taking into account potential pressure variations, must be painstakingly matched to the system's necessities. Neglecting these issues can lead to devastating failure and safety threats.

Icy Globe Valve Composition Harmony Guide

Picking the appropriate component for cryogenic ball valves is paramount, given the intense temperatures involved. This directory highlights common compounds and their performance when exposed to cryogenic fluids such as cryogen nitrogen, coolant helium, and oxygen. Stainless steels, particularly categories 304 and 316, often demonstrate adequate toughness and degradation resistance, though martensitic materials require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their workability and safeguard to specific chemicals needs careful evaluation. Copper alloys, while offering some plus points, may exhibit declined productivity at these diminished temperatures. Consultation with distributors and comprehensive scrutiny is essential to assure permanence and trustworthiness in cryogenic environments.

Enhancing Twin Seal and Vent Framework Functionality

Realizing optimal effectiveness in double shutoff and vent installations hinges on a multifaceted approach. Careful analysis of unit selection is critical, with a focus on substance compatibility and impact assessment. Regular review of bleed channels for obstruction is vital, often demanding the use of exclusive diagnostic machines. Furthermore, protocol boosting—including inspection of transit rates and impact differential—can substantially amplify overall construction consistency and defense. Finally, congruence to creator principles and the application of a complete care agenda are mandatory for long-term sustainability and continuity.

integral block and bleed valve

integral block and bleed valve