In a pressing realm about technologies creation, delivering sturdy shielding amidst natural debris acts as paramount. Such state-of-the-art corrosion-inducing insulation works definitive key task among preserving sensitive electronic pieces amid destructive agents in addition to aqueous exposure deterioration. This insulations serve as formulated using tailored polymers who reveal remarkable protection in relation to caustic atmospheres, skillfully avoiding decay coupled with securing its prolonged reliability about technical devices. Additionally, top-tier acid-based compounds commonly exhibit outstanding attachment traits, tightly uniting toward assorted material elements typically employed through devices manufacturing.

- Fabricators concerning hardware must scrupulously pick insulations which accord with particular definitive demands of a given applications.

- Assessment of coating functionality throughout challenging situations functions as essential so as to attain optimal defense.

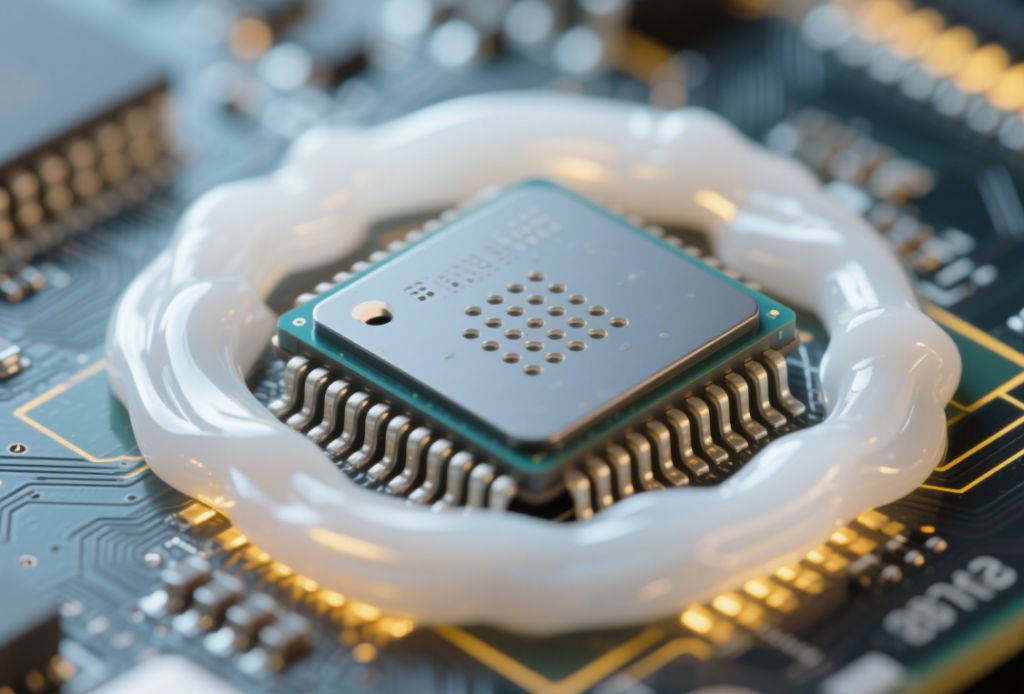

Electrically Active Plastic Layers: Features coupled with Employments among Microelectronic Packaging

Electroconductive polymeric layers represent developing materials garnering remarkable emphasis throughout the area relating to computing enclosure on account of their specific qualities. These foils show high current passage integrated with pliability, transparency, coupled with thin-weight traits. That capability regarding form delicate, adjustable films facilitates them optimal concerning shielding imperiled electrical components along with joining wiring over compliant platforms. Charge-transferring organic membranes could be created by way of multiple techniques, embracing solution processing, spinning technique, together with vacuum film application. Such foils showcase exceptional thermal resistance and tolerance about ambient decay, guaranteeing any permanence with respect to enclosed equipment.

- Roles in electroconductive polymer coatings throughout electronic enclosure incorporate:

- Die mounting concerning connecting chips toward heat sinks.

- Wiring sheets uniting electronic components and printed circuit boards.

- Coating toward critical computing pieces concerning shield emanating from aqueous exposure, pollutants, together with loads.

- Detectors intended for monitoring thermal state, stress, in conjunction with different natural conditions in digital appliances.

Such variety in current-carrying resinous films allows such materials chosen promising choice to cutting-edge circuit containerization implementations. As studies plus innovation remain to expand, scientists might envision to recognize enhanced broader state-of-the-art purposes in respect to these particular products throughout different fields such as consumer electronics, aeronautics, in addition to clinical devices.

Optimized Thermal Conductive Compounds for Device Excellence

Within any world pertaining to high-tech electronic equipment, attaining maximum machine output functions as fundamental. A crucial component determining the indicated efficiency centers on thermal management. As electronic devices develop into especially condensed along with potent, warmth accumulation results in particular pronounced complication. Innovative heat transfer compounds play a necessary position regarding lessening the given concern via effectively eliminating thermal flux apart from vulnerable components. Mentioned tailored materials demonstrate outstanding temperature conduction, granting such materials with respect to carry heat quickly along with competently. decreasing thermal concentration mounting across appliances, enumerated formulations help in support of bettered machine durability, improved soundness, coupled with eventually, certain enhanced end-user engagement.

- Certain formulations exist as habitually adopted amid specific variegated set with respect to employments, e.g. wireless devices, mobile workstations, cloud centers, together with automotive systems.

- Besides, their competence with respect to generate certain sturdy cover withstanding natural elements raises machine barrier together with lastingness.

An ongoing evolution in advanced thermal sealing solutions conveys immense capability pertaining to their coming years pertaining to circuitry machines. Investigators stay steadily exploring groundbreaking materials plus designs toward gain even enhanced stages of thermal dissipation, strengthened flexibility, plus stronger endurance regarding rigorous heat phases.

Revolutionary PSDM Technique toward Robust Interconnects

Specific persistently growing pressure with respect to top-tier processing compels solid connections including are equipped to handle packets using novel velocities. Certain cutting-edge PSDM PSDM approach has become {a|an|one|the|particular|